Team With Us

Offering capabilities to complement your needs

DRA is prepared to team as prime or subcontractor to provide a successful partnership to meet contract requirements and exceed customer expectations. DRA is well versed in the SBIR/STTR process and has transitioned several through to SBIR Phase III contracts. Below are some of many previous and current customers and partners.

Partners

Sensor/System Testing

At DRA, there are multiple laboratories on site with state-of-the-art technology to conduct research and development of prototypes such as the Test and Integration Laboratory, the Optics Laboratory, and the Systems Integration Laboratoy (SIL). DRA also builds Data Acquisition Units to support sensor/system testing and analysis.

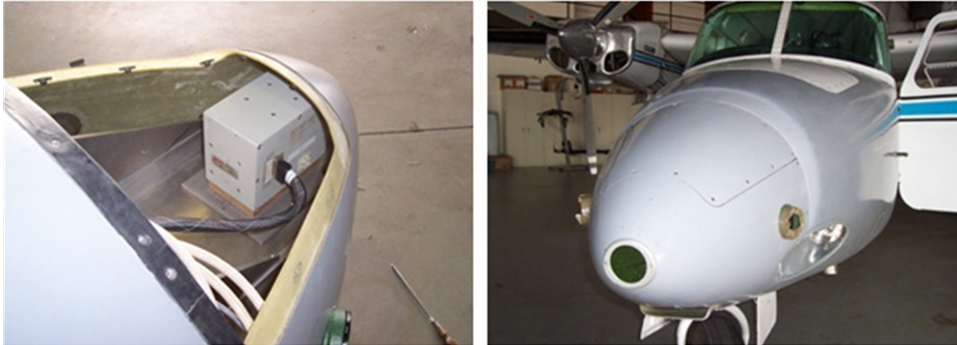

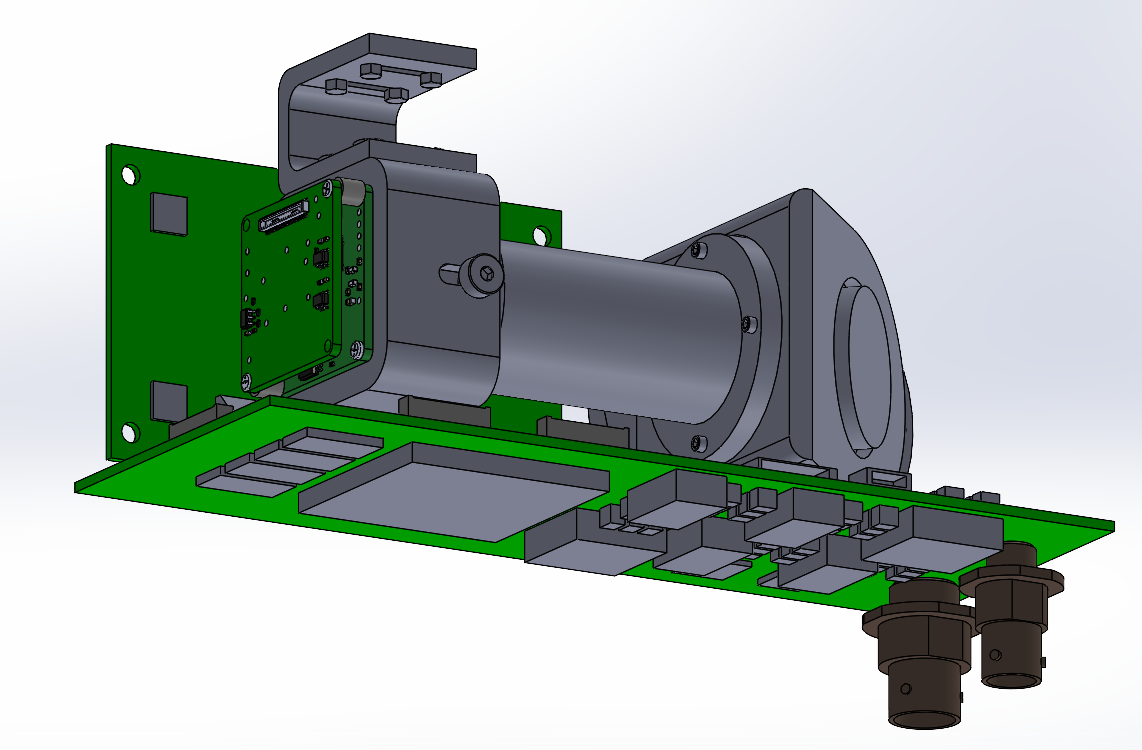

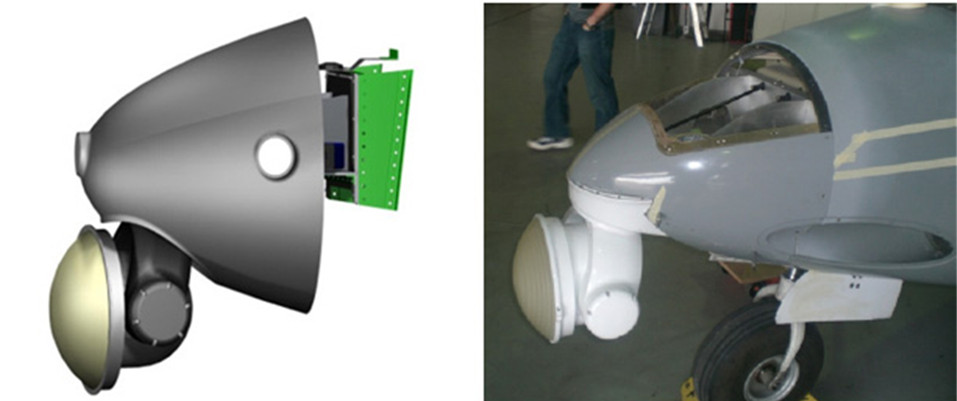

Testbed Aircraft

DRA uses test bed aircraft to support flight demonstrations for various programs. DRA, using state-of-the-art design tools such as SolidWorks 3-D, designs and fabricates custom sensor housing for a variety of aircraft that meet FAA requirements. Sensor mount points are available in the nose, tail and belly of the aircraft. Computer and diagnostic equipment can be installed in the cargo area or in the back four seats. Heavy-duty power supplies provide electricity at 28V DC or 115V AC. This aircraft offers a unique combination of utility and affordability.

Test and Integration Laboratory

DRA maintains a test and integration laboratory to support the design, development and testing of electronic sub-assemblies and systems for digital signal processing applications. State-of-the-art work stations equipped with the latest releases of schematic capture, PCB design viewer tools, Field Programmable Gate Array (FPGA) development tools for VHDL code generation, simulation, hardware synthesis, hardware-in-the-loop testing, and CAD tools for the design and 3-D renderings of mechanical apparatuses and housing designs are maintained. Networked workstations provide parallel analysis capabilities for complex designs to maximize engineering throughput throughout the design process.

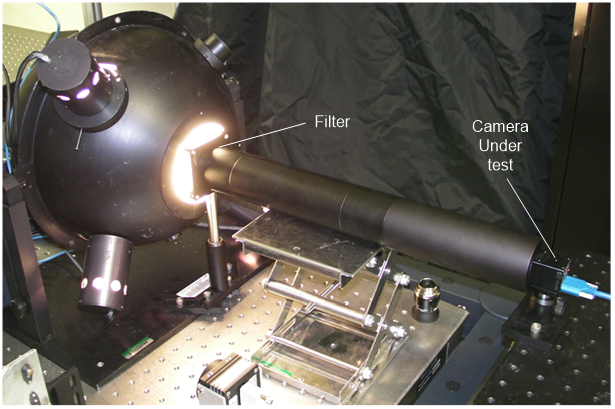

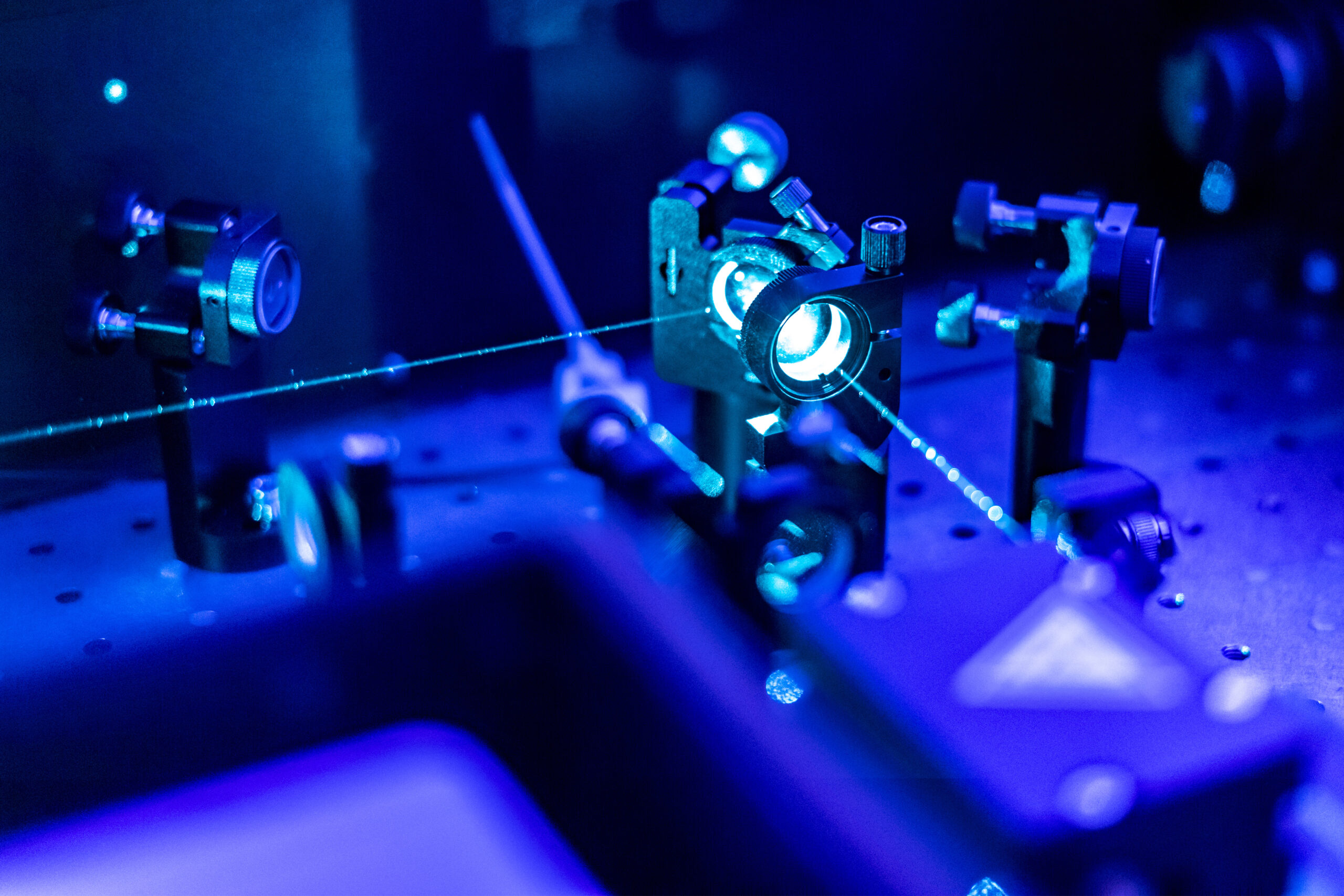

Optics Laboratory

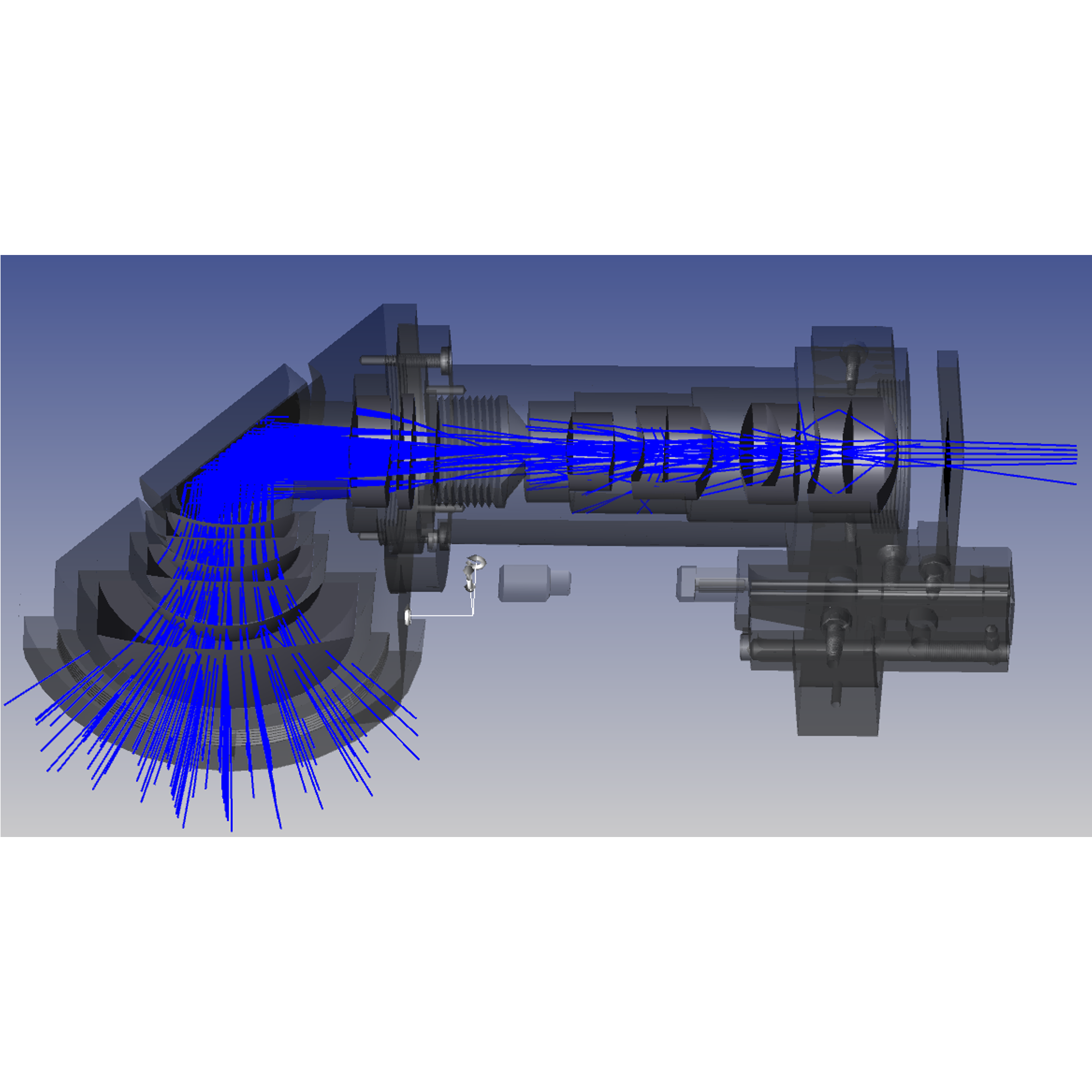

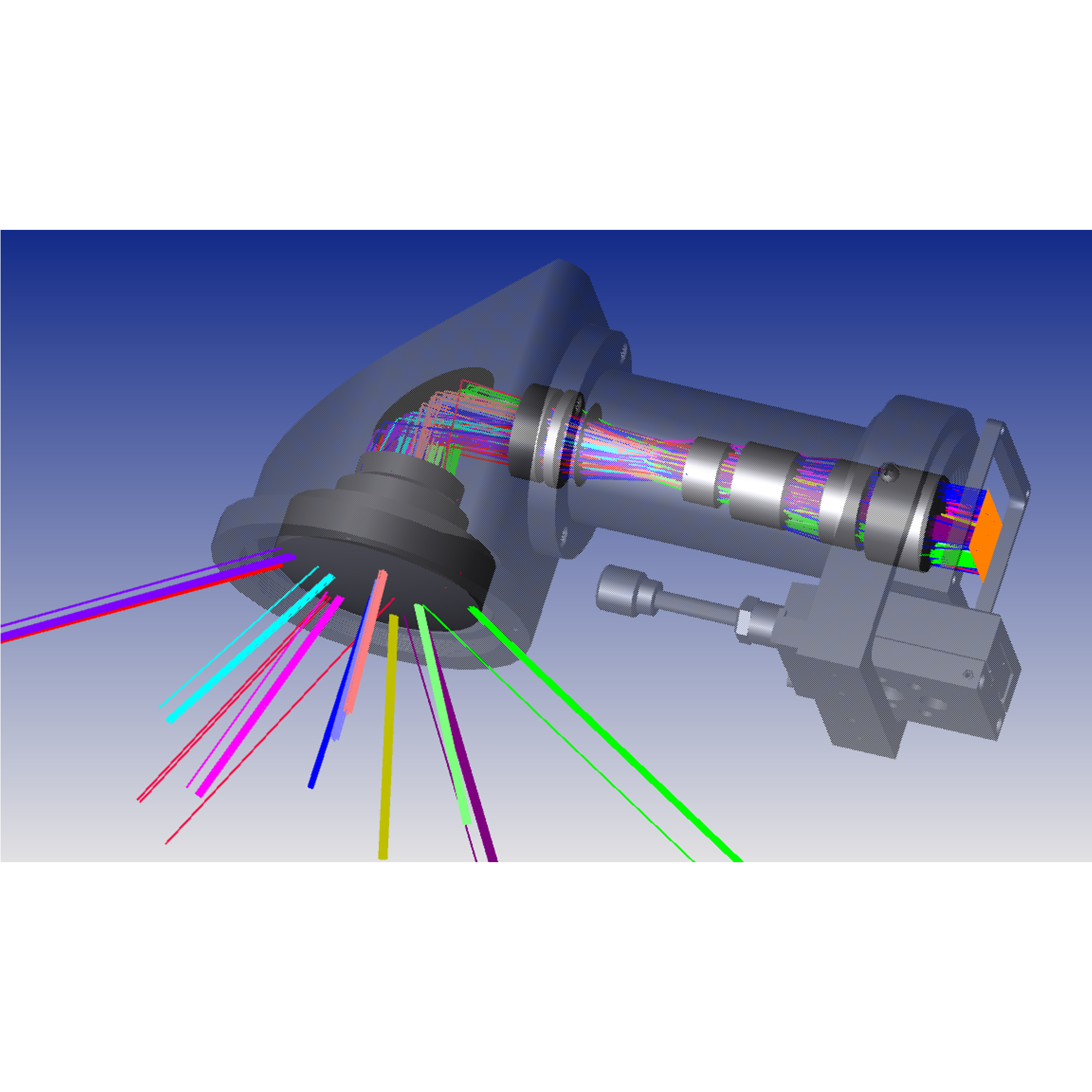

DRA has developed an optics laboratory to conduct research and development of electro-optical and infrared sensors. Work in this laboratory provides the physical foundation for ideas and concepts for new sensors. DRA also builds and tests initial prototypes to demonstrate proof-of-concept. The optics lab also provides the capability to conduct calibration and performance analysis of optical systems.

Systems Integration Laboratory

DRA has developed a one of a kind laboratory with both custom software and hardware to enable HW/SW integration testing and HW/SW In-the-Loop (HITL/SITL) testing in a static free and environmentally controlled environment. Work surfaces are covered with properly grounded anti-static mats and the lab has its own thermostat and HVAC system. DRA built custom computers that have the ability to either record live sensor data, or playback previously recorded sensor data. The SIL features various connections to the outside. A VHF antenna is on the roof to allow DRA personnel to monitor and communicate with flight testing activities. Two GPS antennas are on the roof, one is a passive antenna for the INS in use by DRA, and the other is for GPS timesync for recording live sensor data.

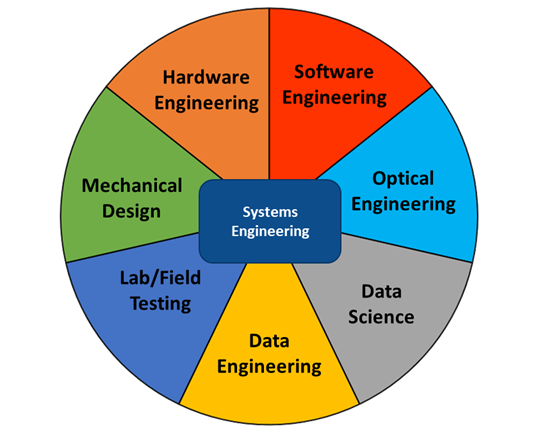

Systems Engineering

With every project at DRA, the engineers work with the customer to understand the primary objectives of the project. Systems engineering principles are used throughout the product development lifecycle to refine the requirements and validate the results. Throughout the project, the engineers employ the following systems engineering techniques:

Systems Engineering Approach:

- Requirements capture

- System design

- Allocation of requirements to subsystems

- Subsystem design

- Subsystem verification

- System integration

- System validation

DRA uses a systems engineering approach to all engineering disciplines. The lead engineers work with the customer to fully understand their requirements, goals, constraints, and priorities of the project. Next, trade studies are performed to understand alternative solutions to develop a detailed design for the system. In many cases, interacting subsystems strongly affect one another and DRA finds a balanced solution that optimizes system performances and cost as part of these trade studies. The system design is partitioned into the appropriate engineering disciplines needed to produce a prototype. A prototype of the design is implemented and tested through unit, subsystem, and system level testing. Ultimately, the performance of the system is validated by demonstrating the system in a relevant environment. The customer is involved throughout the process to ensure the implementation of an efficient, effective and high-quality solution.

DRA has developed a Systems Integration Laboratory (SIL) with both custom software and hardware to enable hardware/software integration testing in a static free and environmentally controlled workspace. Work surfaces are covered with properly grounded anti-static mats, the lab has its own thermostat and HVAC system. Custom computers were built that have the ability to either record live sensor data, or playback previously recorded sensor data.

Modeling and Simulation

DRA has extensive experience developing models and simulations of real-world problems such as:

- Synthetic target imagery of objects using Generative Adversarial Networks (GAN)

- Synthetic detection models using EO/IR/RF

- Multi-physics acausal modeling

- Synthetic target kinematics

- Fast Line-of-sight Imagery for Target and Exhaust-plume Signature (FLITES)

- Digital Twin

- Digital Transformation

Digital Twin is a virtual model which can be simple as a representation of projectile motion or a culmination of multiple simultaneous physical phenomena. The primary goal of modeling is to inexpensively, safely, and quickly iterate potential solutions to the system being modeled. The benefits of creating and using virtual models include: better research and development for creating the most optimal solution, lower maintenance costs as issues are predicted and corrected before production, and safely performing system scenarios. DRA uses digital twins, models and simulations where possible to produce the best solution.

Under NATO research program, DRA developed multi-physics models for electro-mechanical systems subject to external gravitational and aerodynamics forces. With the integration of Generative Adversarial Networks (GANs) and computer aided designs (CAD), DRA generated artificial image distributions of UASs to be used in training counter-UAS (CUAS) detection algorithms under DARPA. Along with this, DRA has implemented system physical models for real-time hardware-in-the-loop testing of aircraft components.

AI and Algorithm Development

DRA has extensive experience building novel model-based algorithm designs using Artificial Intelligence (AI), Machine Learning, and other optimization techniques. DRA engineers can develop quantitative problem descriptions and model the problems in a meaningful way. Engineers can then evaluate multiple approaches to solving the problem while analyzing tradeoffs between computational constraints and performance requirements. Using a spiral design approach, iterative lessons learned are used to shape concepts into algorithms that provide the best solutions. This approach has assisted DRA in developing algorithms to solve challenging problems in the following areas:

- Image processing

- Object classification

- Sub-pixel object detection

- Signal detection and characterization

- Sequence analysis

- Object tracking

- Control applications

DRA develops a computer vision algorithm to perform real-time sub-pixel object detection and track aircraft at ranges greater than 15 nautical miles.

Software Engineering

DRA has the experience to develop the right software solution for your project needs. Embedded systems using real-time operating systems (RTOS) or desktop Graphical User Interfaces (GUIs), DRA has broad experience in all aspects of software development. DRA can apply the following software languages, tools, techniques, and standards to ensure a successful result:

Proficiencies in:

- Java

- Python

- C/C++

- MATLAB

- Assembly

- Linux/Windows

- VxWorks

- PetaLinux

- Embedded Systems/System-on-Chip (SoC)

- Eclipse

- Qt Designer

- Future Airborne capability Environment (FACE)

- Vehicle Integration for C4ISR/EW Interoperability (VICTORY)

- GUIs

- Real Time Operating Systems (RTOS)

DRA has diverse software experience through project development in the DoD and commercial sectors. DRA uses a spiral development approach in developing complex multi-box systems communicating over custom interfaces. DRA has also developed software following documented standards such as FACE and VICTORY.

The variety of software development tools available allows DRA to choose the best ones for the job. Recent examples include:

- Qt Designer and Python were used to create GUI-based tools for testing, analysis and simulations.

- A multi-tasking detection and tracking application was developed using VxWorks and C/C++

- Designers used PetaLinux and Python-based libraries to create HTTP browser-based graphical control interfaces for RFSoC and MPSoC.

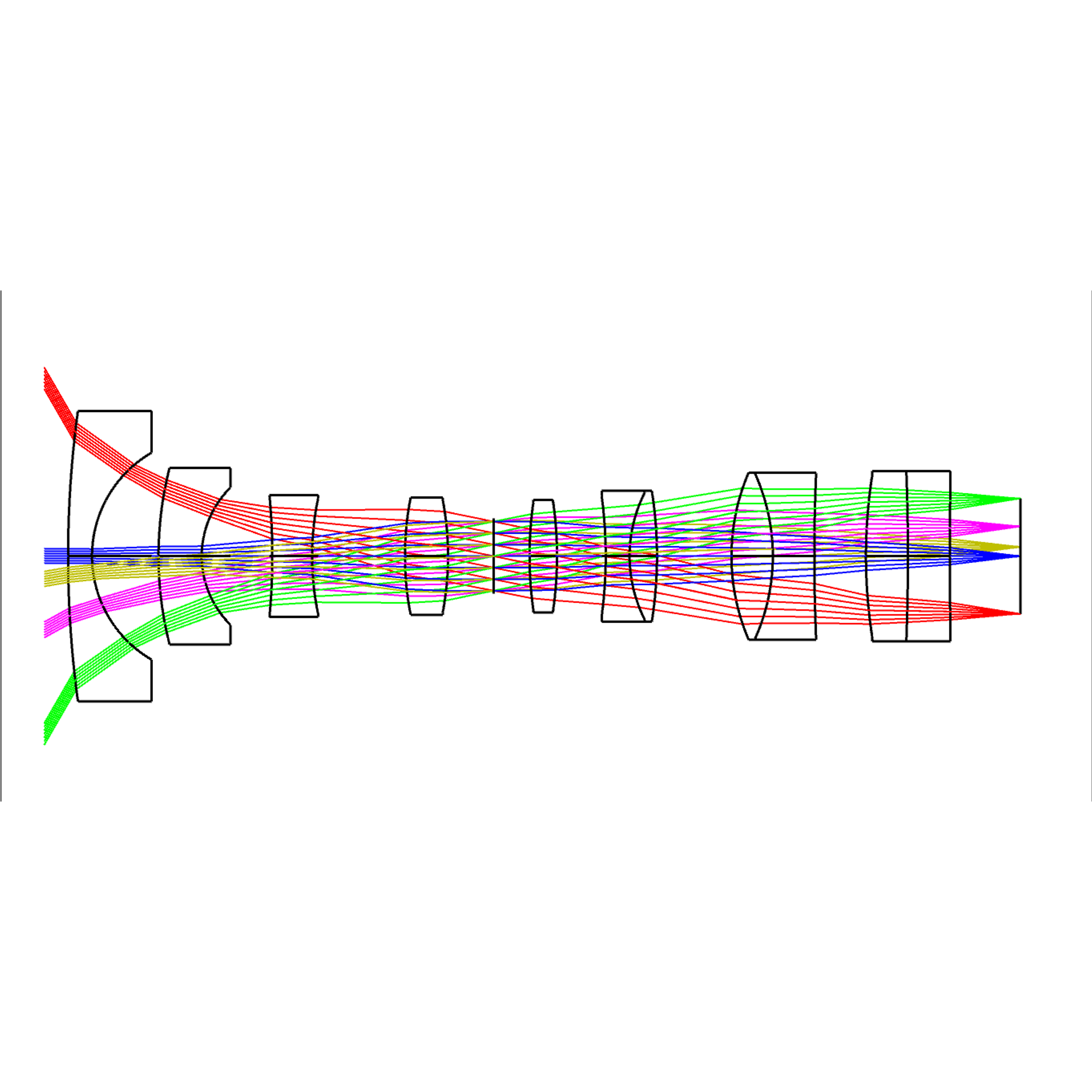

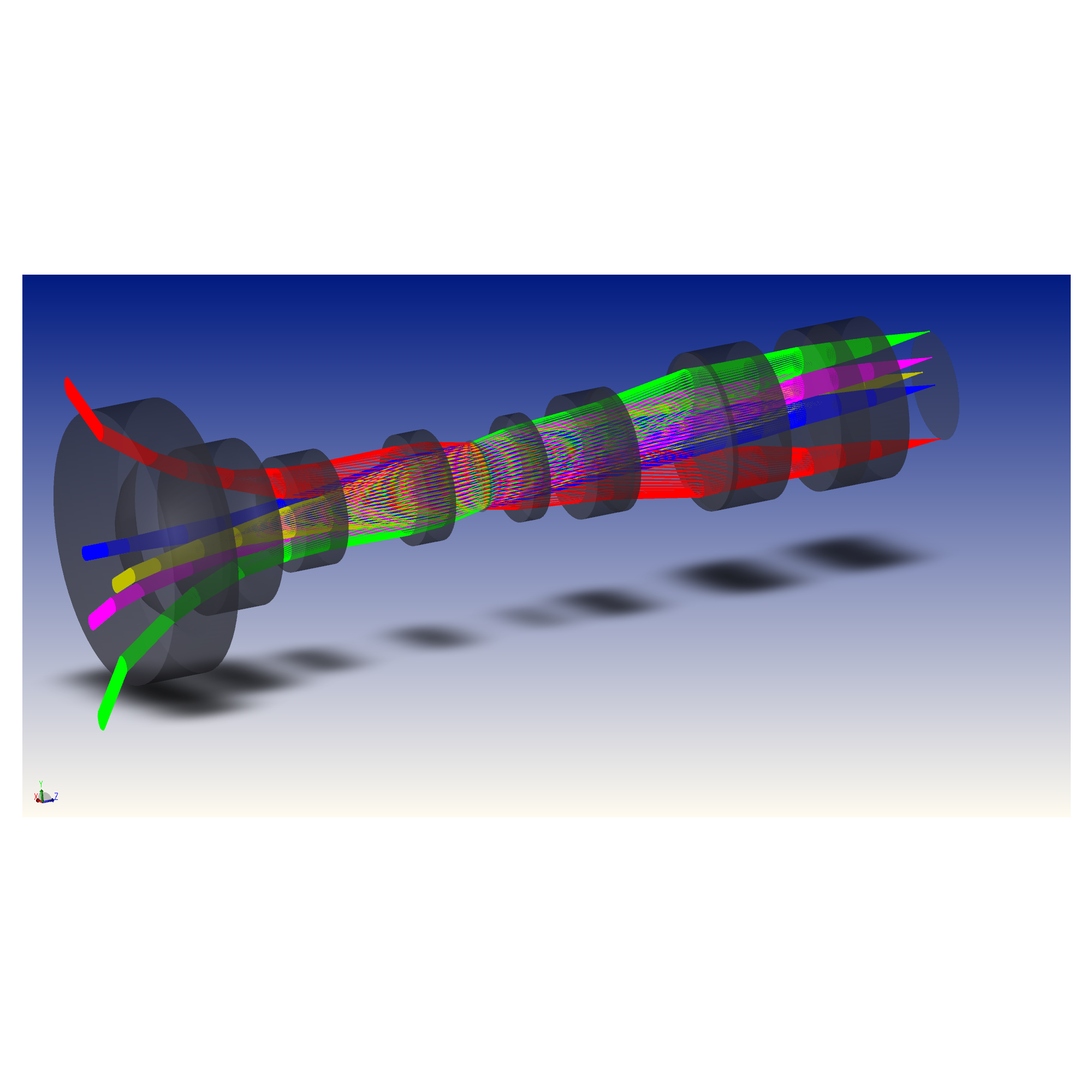

Optical Design

DRA’s expertise in passive and active remote sensor development allows DRA to design and simulate custom Electro-Optical solutions for specialized sensing challenges. As part of the optical design process, DRA employs the following tools and techniques:

Proficiencies in:

- Zemax OpticStudio lens design

- MODTRAN

- LiDAR design

- FRED stray light analysis

- Radiometry

- Wave optics simulations

- Optics lab characterization

DRA can generate build to print spec sheets for optical fabrication vendors, who verify performance and manufacturability. DRA’s designs demonstrate great control over optical aberrations and imaging performance over a wide set of wavelength, field of view and package limited scenarios.

Most optical sensor development goes through testing in DRA’s Optics Lab, which supports testing via free space optics, diffractive elements, filters, fiber-optics, lasers, a monochromator, an integration sphere and various photodetectors, cameras, sources and test targets for evaluating image quality and performance. DRA follows the EMVA1288 international standard for evaluating sensors.

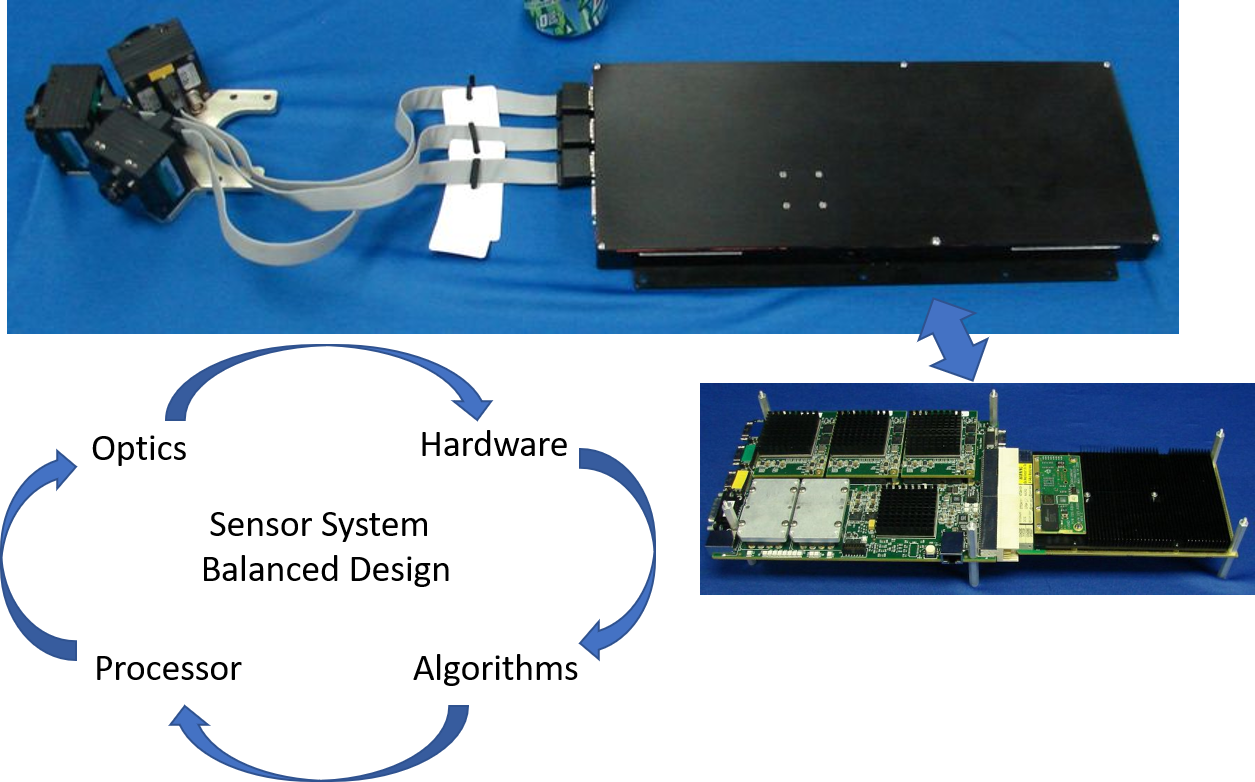

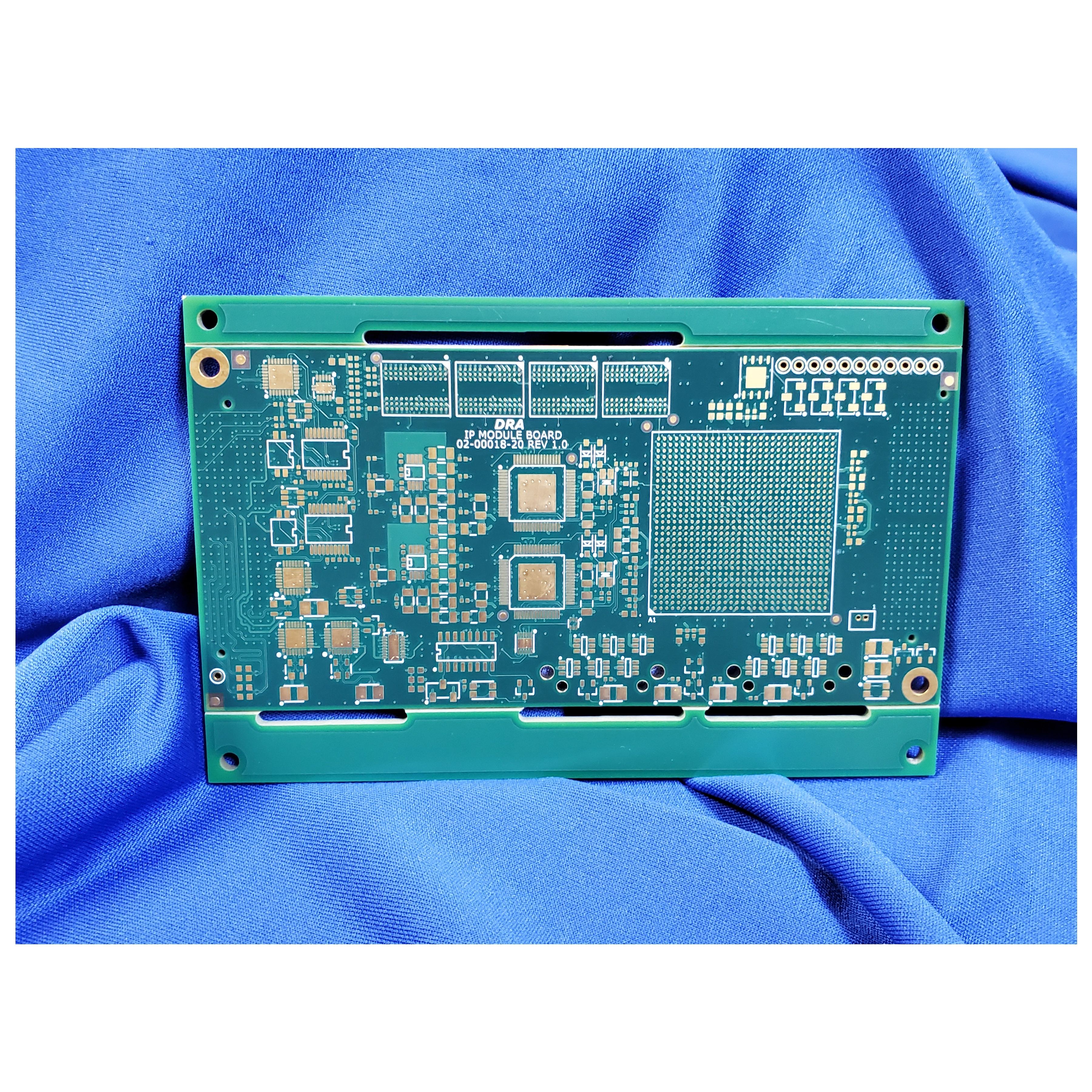

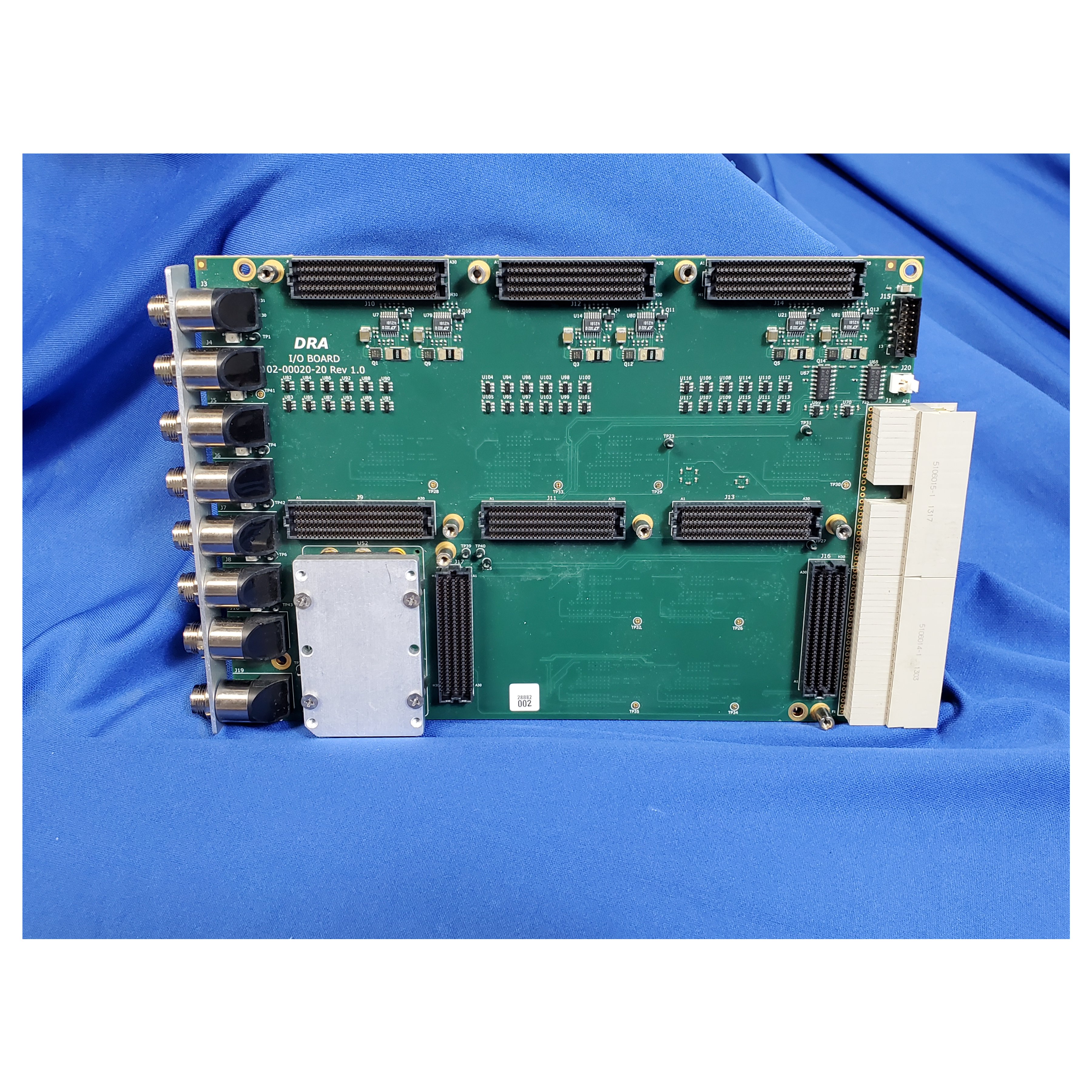

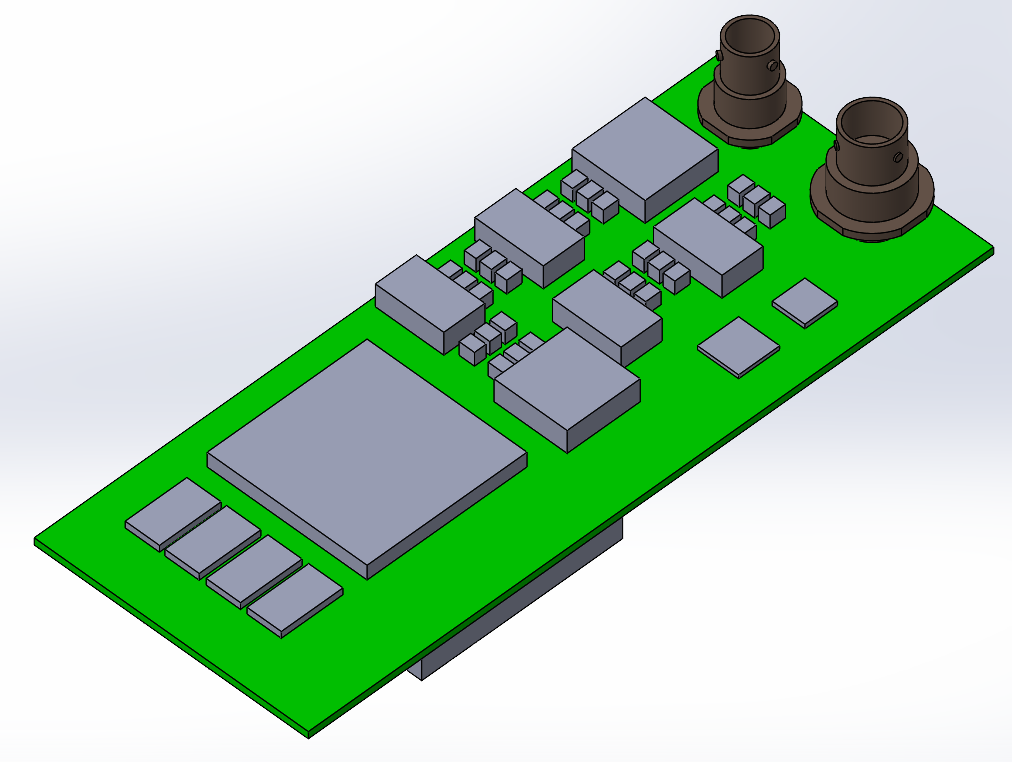

Digital Hardware Design

DRA offers comprehensive Hardware Design Services with leading edge expertise in Xilinx Field Programmable Gate Array (FPGA), Multiprocessor System-on-Chip (MPSoC), and Radio Frequency System-on-Chip (RFSoC) technologies. The digital team uses the following tools and techniques including the latest technologies from Xilinx and third parties for code generation, simulation, and hardware-in-the-loop testing:

Proficiencies in:

- FPGA, MPSoC, RFSoC firmware and software development

- VIVADO

- VITIS

- ALDEC

- Conversion of software algorithms into VHDL for real-time processing

- System level testbench generation and design verification

- Synthesis and timing analysis of FPGA designs

- Custom analog/digital circuit design

- Printed Circuit Board (PCB) design, fabrication, and assembly

- On-site product integration and hardware-in-the-loop testing

- Reverse engineering sequential C/C++ and MATLAB code to VHDL for real-time parallel processing execution

DRA can translate and optimize customer provided C/C++ and MATLAB algorithms into FPGA parallel-processing architectures to support real-time processing needs. DRA can provide turnkey hardware solutions that leverage Commercial-off-the-Shelf (COTS) development boards, or design custom electronics as needed such as backplanes and FPGA, MPSoC, and RFSoC processing board and modules.

DRA has a proven background in developing custom MPSoC software and FPGA firmware for numerous applications that include compact Unmanned Aerial Vehicle (UAV) image processing systems, portable laser detection systems, and large-scale, ground-based Radio Detection and Ranging (RADAR) systems.

Services

DRA services provide product support and related services to enable our customers to develop and enact sound and effective product support strategies. Through collaborations with stakeholders, customers can rely on DRA to provide optimal solutions and mitigation strategies to problems and challenges presented throughout the product lifecycle. Employees use the following expertise to cover both DoD hardware and software platforms and systems:

Proficiencies in:

- Program Management

- Requirements Definition

- Integrated Logistics Support

- Technical Data Management

- Post Production Support

- Inventory Management

- Test and Evaluation Support

- Technical Documentation

- Change Management

- Disposal Support

- Systems Administration

- Configuration Management

- Systems Engineering

- Operational Employment

- Supply Chain Risk and Evaluation

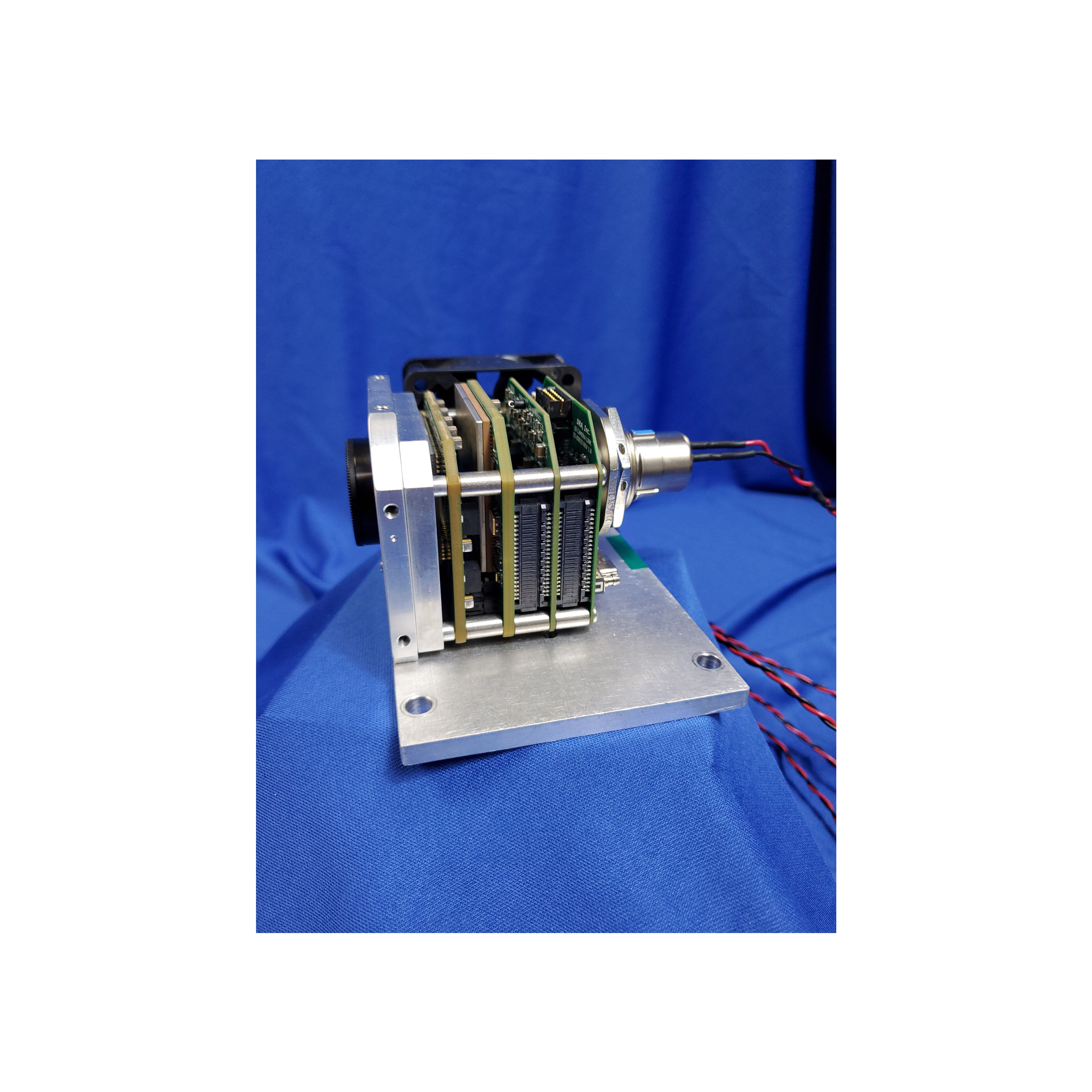

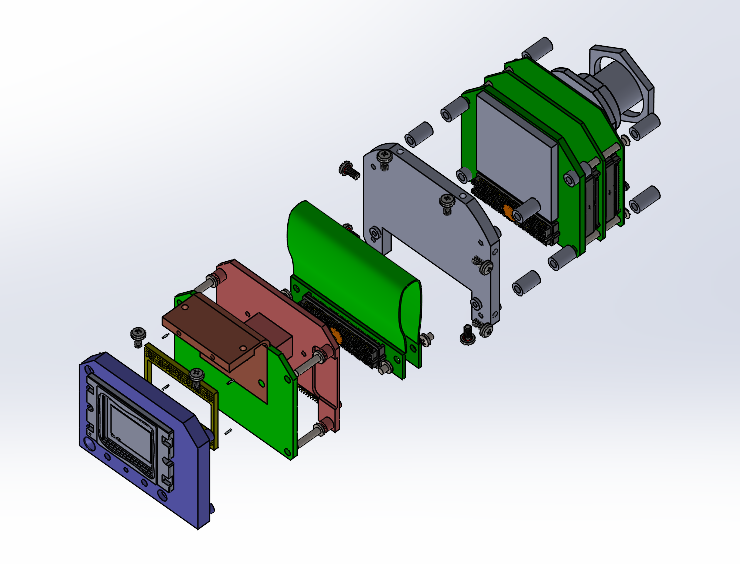

Mechanical Design

Many projects have physical requirements and constraints which need to be considered in the overall system design. DRA’s engineers apply mechanical models during development to understand the physical interdependencies of the components and to ensure a successful build of the product. DRA utilizes the following tools and techniques to aid in the mechanical design process:

Proficiencies in:

- SolidWorks

- 3-D modeling and 2-D CAD

- Rapid prototyping

- Environmental Stress Testing

- OrCARD PCB board layouts

SolidWorks provides solid modeling computer-aided design (CAD) capabilities. 3-D renderings are produced, along with animations to evaluate the form-fit-function of a design prior to manufacturing. This includes taking industry standards STEP files from commercial products all the way to DRA custom OrCard PCB board layouts and incorporating them into an integrated design. DRA uses established procedures for the conversion of 3-D renderings into 2-D mechanical diagrams to support the manufacturing process. Partnerships with local machine shops as well as working relationships with additive manufacturing companies produce everything from rapid prototypes to high-quality, low-cost, custom fabricated solutions.